Experience an no-code, contemporary cloud manufacturing ERP software that streamlines production cycles, tracks material consumption, facilitates capacity planning, manages subcontracting, and beyond!

Integrate your production planning with shop floor operations effortlessly using ERPNext. Its comprehensive suite of features, spanning customer management, sales orders, inventory, purchasing, accounting, and financial reporting, ensures seamless real-time coordination across all your business verticals.

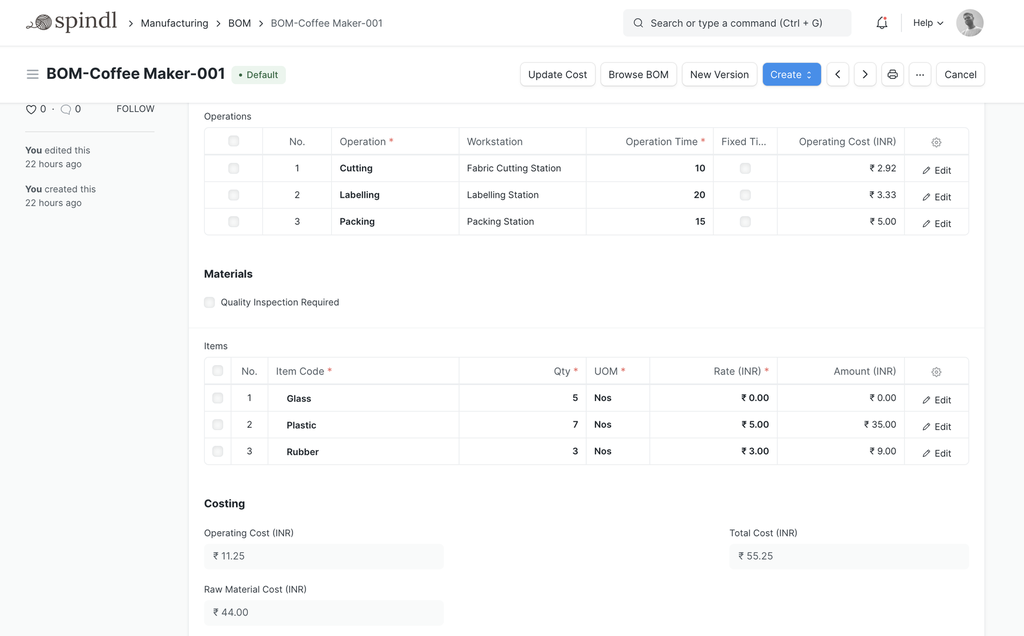

A bill of materials (BOM) lies at the core of any cloud manufacturing software, and ERPNext ensures robustness and accuracy with its well-defined BOM structure. Hierarchical in nature, the BOM places the finished product at the top, accompanied by product codes, part descriptions, quantities, costs, and additional specifications for comprehensive clarity and precision.

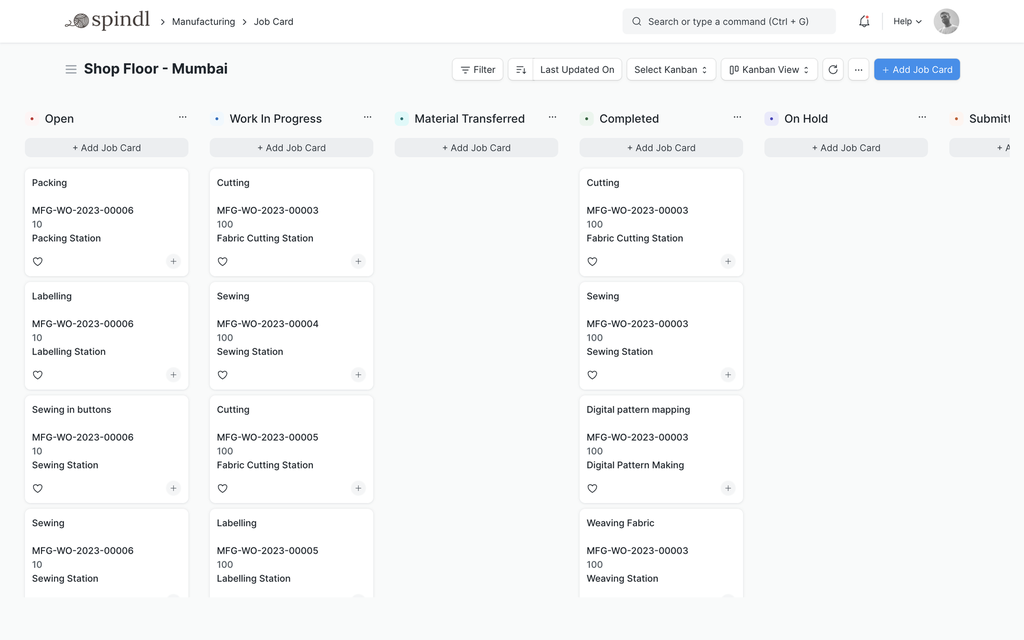

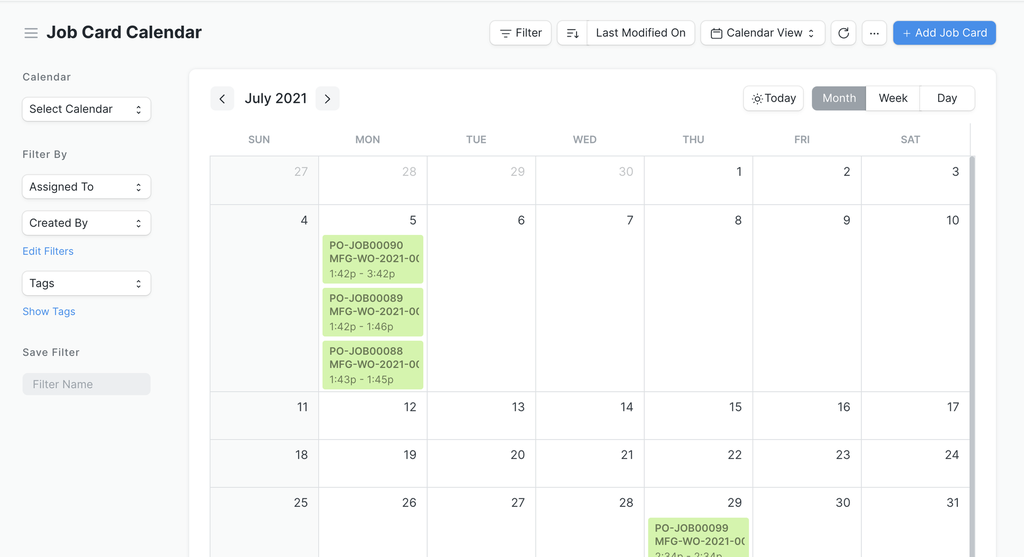

Utilize ERPNext's job cards, operations, and workstations features to seamlessly capture daily activities on your shop floor. Gain insight into the real-time status of job work, including product manufacturing progress, workstation locations, employee assignments, and pending steps for each work order—all conveniently accessible on a single screen.

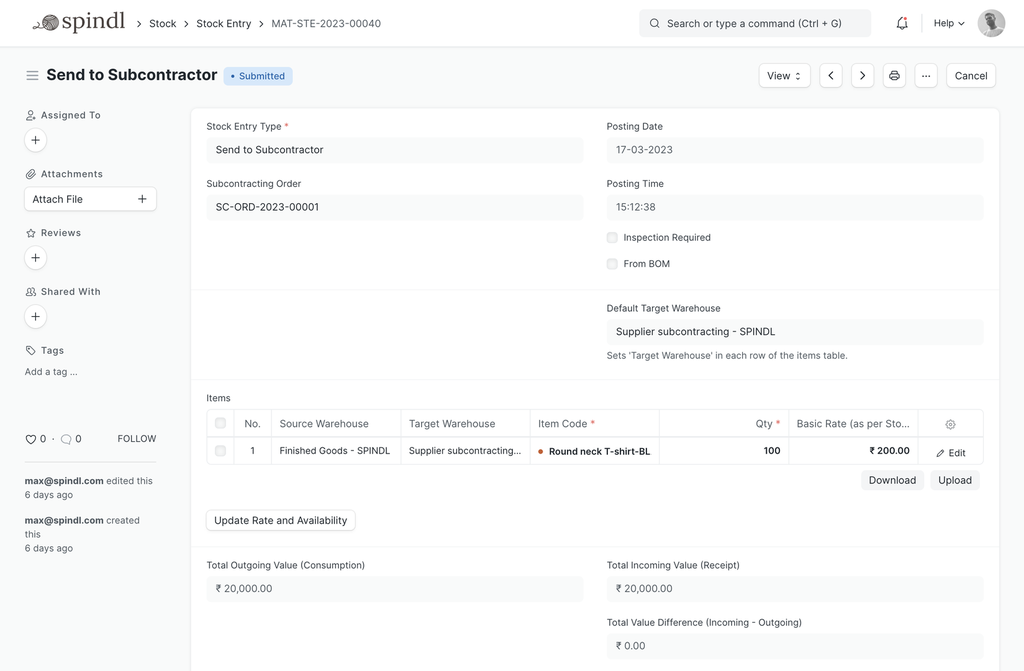

Explore ERPNext's subcontracting feature if your business involves outsourcing processes to suppliers. This functionality simplifies the supply of raw materials and enables tracking of supplier labor and operations. Finished goods are valued based on the costs of raw materials and procured services, ensuring accurate accounting.

In ERPNext, if you produce t-shirts in various sizes and colors, you'll need to monitor each type and its variants, referred to as item variants. The primary item is stored as an item template, while each variation is stored as an item variant. You can record various attributes like color or size for each item variant, facilitating comprehensive inventory management.

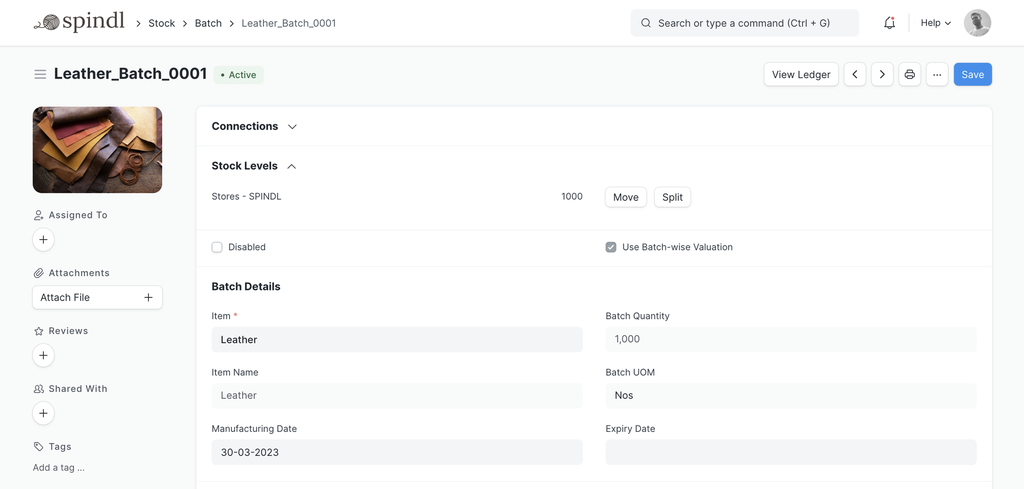

Effortlessly manage batched items with ERPNext's integrated inventory system. Its real-time view of product availability ensures you have access to crucial details such as manufacturing dates, expiration dates, and more for each batch. Additionally, you can quickly search through your stock and make informed decisions by scanning item barcodes using your device camera, enhancing efficiency and accuracy in inventory management.

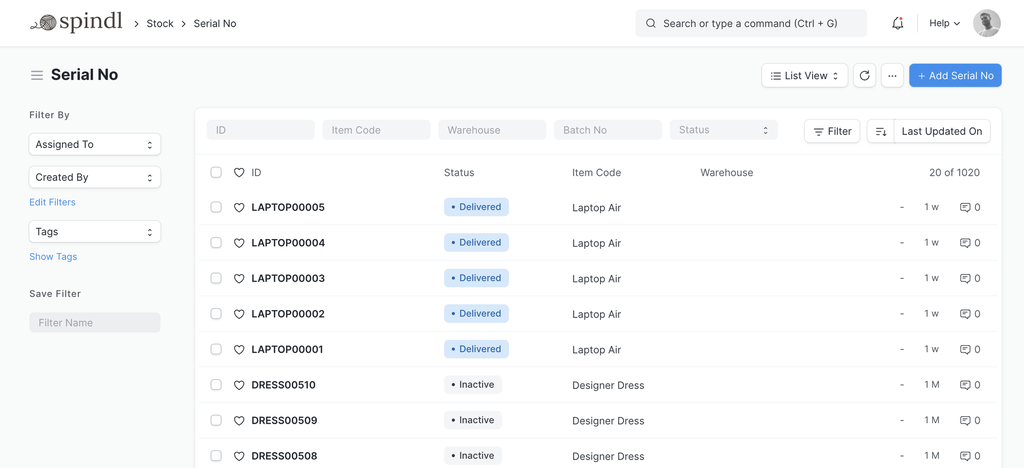

Leverage serial numbers to uniquely identify units within ERPNext. By setting up naming series, the system automatically generates serial numbers for new stock items. Additionally, streamline stock management by scanning item barcodes using your device camera for quick and efficient search capabilities across all your inventory.

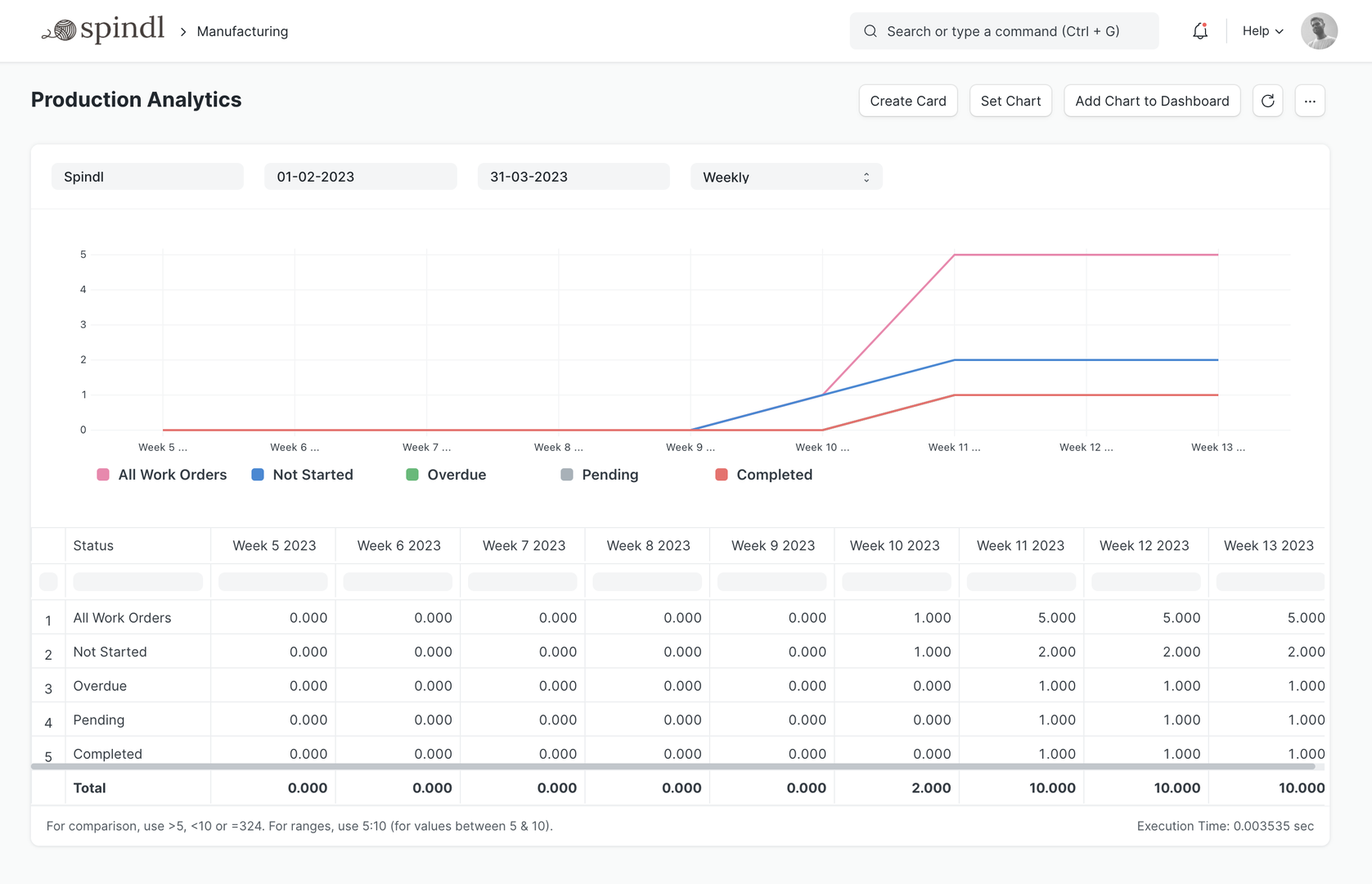

From work orders against sales to material requests, ERPNext provides comprehensive visibility into every aspect of your Material Requirements Planning (MRP) process. Track material consumption of serialized or batched inventory to control expenses and minimize resource wastage effectively.

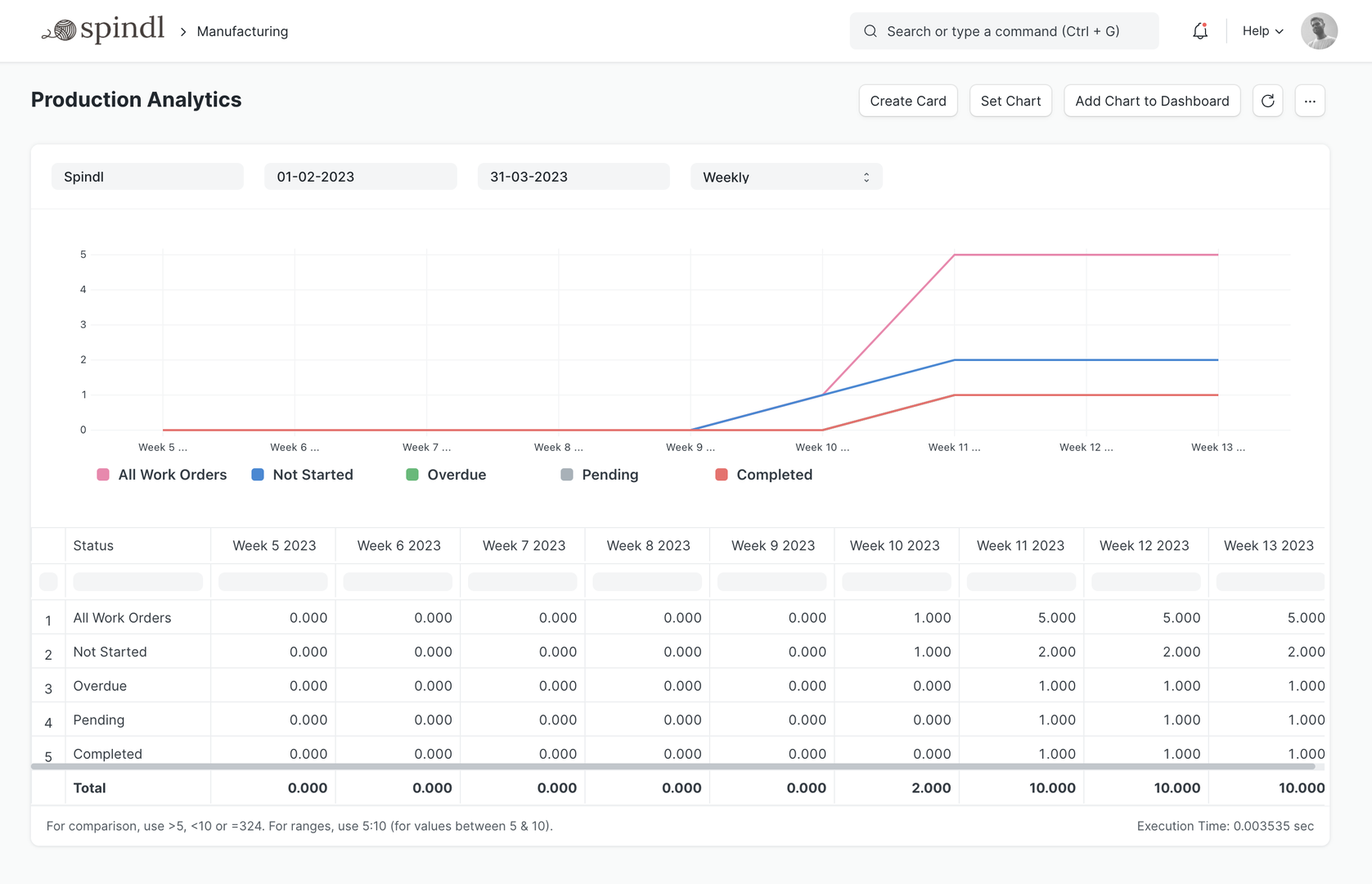

Maximize efficiency by optimizing workstations according to available resources for open production orders. Identify and resolve bottlenecks on the shop floor with a capacity plan. Additionally, efficiently manage planning schedules for a predetermined period, such as 30 or 45 days, to streamline operations and enhance productivity.

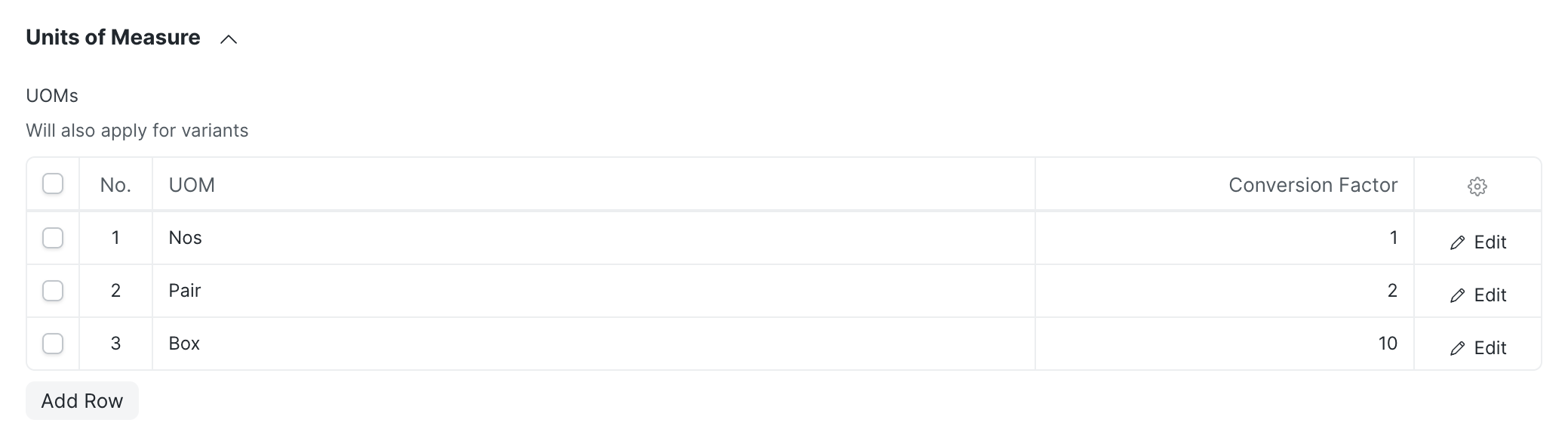

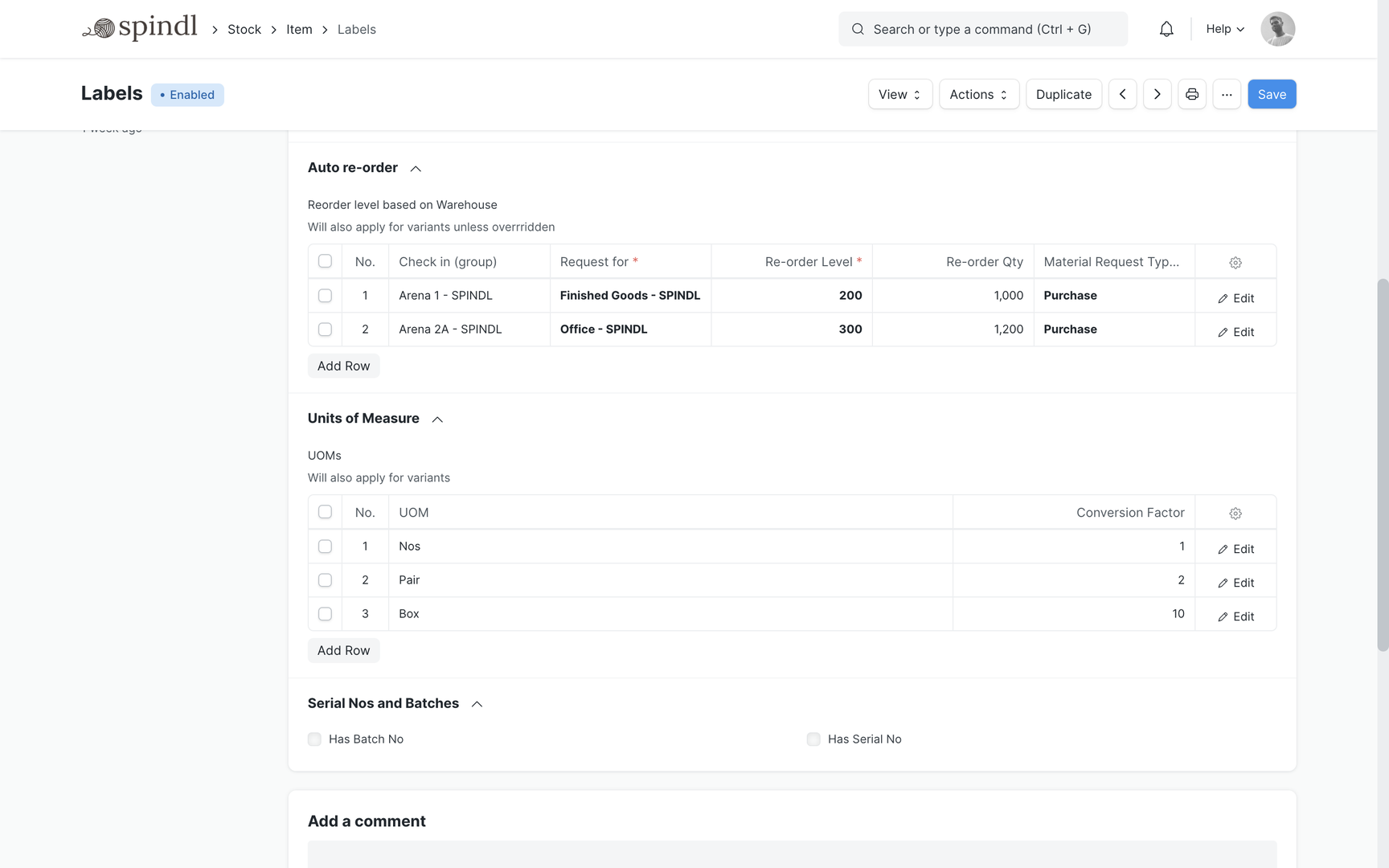

Maintain precision in material measurements tailored to your needs with ERPNext. Track various units of measurement for your inventory seamlessly. Set up conversion factors directly in the Item master, enabling smooth sales, purchase, and stock transactions. Let the system handle all conversions effortlessly, ensuring accuracy and efficiency in your operations.

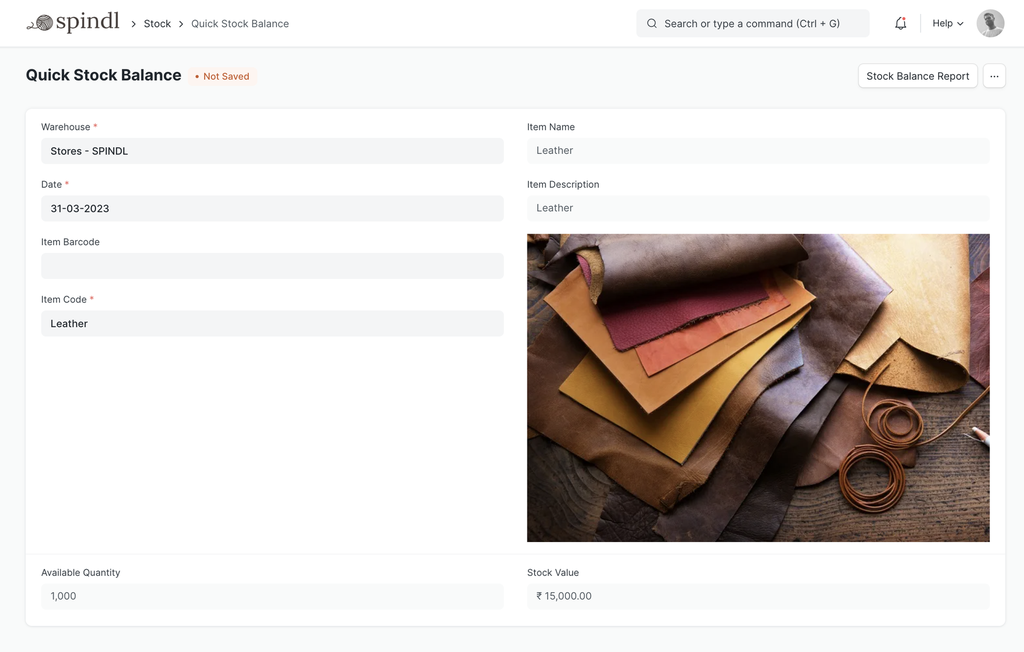

Easily conduct stock audits with the quick stock balance report in ERPNext. Verify warehouse stock by comparing it against the logged stock in the system. Simply use any device to scan a barcode—no barcode scanner needed—and begin counting inventory with ease.

Ensure inventory availability and prevent stockouts by tracking an item's reorder level in ERPNext. When the stock level falls below the reorder threshold, the system automatically generates a material request. This proactive approach enables you to replenish inventory precisely when needed, minimizing the risk of stock exhaustion and ensuring smooth operations.

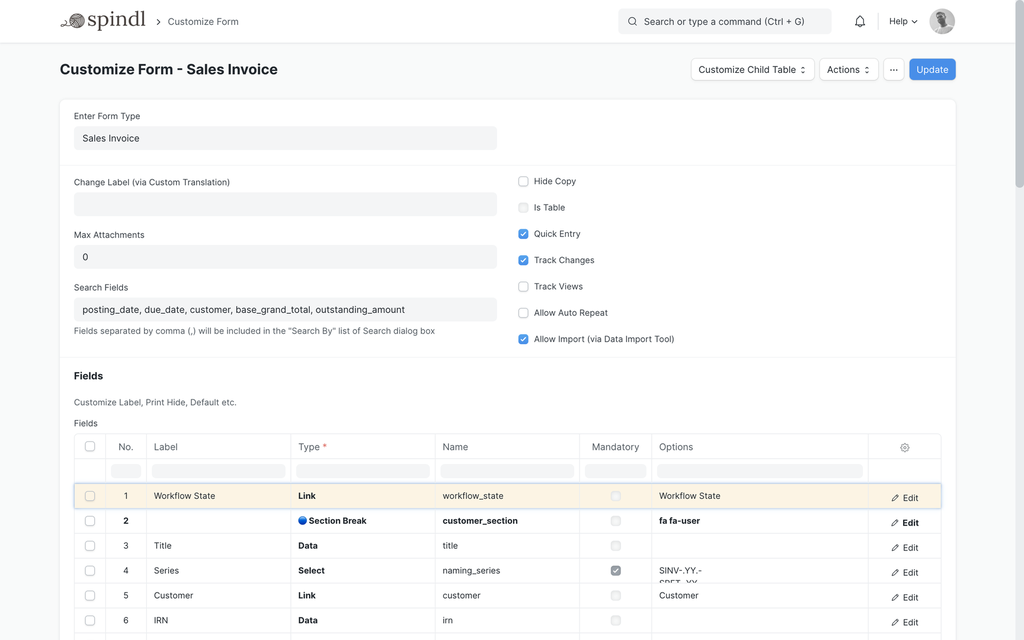

Develop your tailored cloud manufacturing ERP software effortlessly. Map critical data by incorporating custom fields into forms. Customize form behavior by auto-fetching values, hiding fields based on user roles, and crafting custom print formats—all achieved without writing a single line of code.

© Copyright 2024 Korecent| All Rights Reserved